Product Description

Imagine you have something really important, like a brand new video game console, an expensive camera, or a set of delicate tools. You wouldn’t just throw it in a box with some crumpled newspaper, would you? You’d want to make sure it’s safe and secure, protected from bumps and scratches during shipping or storage. That’s where Packaging Kite’s custom design foam inserts come in handy. They’re like little protective nests for your valuable items.

What are Foam Inserts?

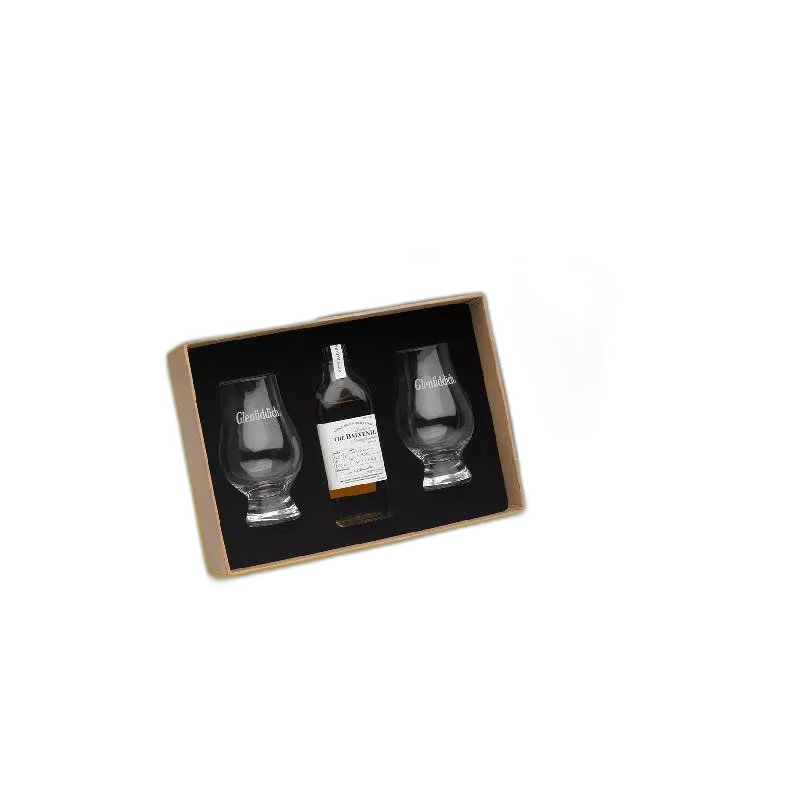

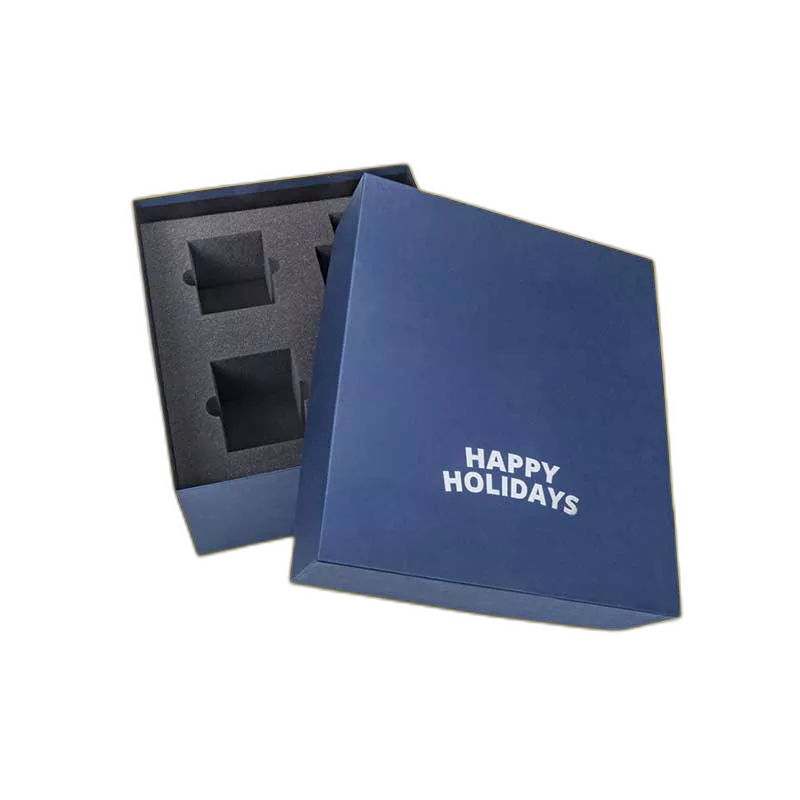

Foam inserts are pieces of foam, cut and shaped to fit perfectly inside a box or case. Think of them as custom made cushions that hold your items in place. They’re made from different kinds of foam, each with its own special ability to protect. Some are soft and squishy, good for delicate items. Others are firm and strong, ideal for heavier things. They can be any color you want, and we can make them fit almost any shape or size.

Why Use Foam Inserts?

There are lots of good reasons to use foam inserts. First, they offer excellent protection. The foam cushions your items and stops them from moving around inside the box. This prevents damage from impacts, vibrations, and scratches. Second, they make your product look professional. A well designed foam insert shows that you care about the quality of what you’re selling or shipping. It gives your customers a good impression. Third, they help organize your items. If you have a kit with multiple parts, a foam insert can keep everything in its place, making it easy to see what’s included and preventing things from getting lost. Finally, foam inserts can be reused. They are not just for one time use; they can be used to store the item safely when not in use.

Types of Foam We Use

Packaging Kite uses several different types of foam to make our inserts. Each type has its own strengths. One popular choice is polyethylene foam, or PE foam. This is a strong, closed cell foam. That means it doesn’t absorb water easily. It’s great for protecting electronics and other items that need to stay dry. We also use polyurethane foam, or PU foam. This foam is softer and more flexible. It’s good for cushioning delicate items and preventing scratches. Another option is anti static foam. This special type of foam prevents static electricity from building up. It is important for protecting sensitive electronic components. The choice of foam will depend on the item needing protection.

Designing Your Custom Foam Insert

Designing your own foam insert with Packaging Kite is easy. First, you’ll need to tell us about the item you want to protect. What is it? What are its dimensions? How much does it weigh? What are its most fragile parts? Once we have this information, we can start designing the insert. We use special software to create a 3D model of the insert, making sure it fits your item perfectly. You can choose the type of foam, the color, and any special features you want. We can even add your company logo to the insert! We will then share a plan for you to approve.

The Manufacturing Process

Once you approve the design, we start the manufacturing process. We use a variety of techniques to cut and shape the foam. One method is die cutting, where a sharp blade is used to cut the foam into the desired shape. This is a good option for simple shapes and large quantities. We also use water jet cutting, which uses a high pressure stream of water to cut the foam. This method is very precise and can be used to create complex shapes. For some projects, we use CNC routing, which uses a computer controlled cutting machine. This is the best option for very complex shapes and intricate designs. No matter which method we use, we make sure the insert is cut precisely and meets your exact specifications.

Applications of Foam Inserts

Foam inserts are used in a wide variety of applications. They are used to protect electronics, tools, medical equipment, musical instruments, sporting goods, and many other products. They are also used in the military and aerospace industries to protect sensitive equipment during transport. If you’re a business owner selling expensive or delicate products, foam inserts are a must have. They protect your products and build trust with your customers. If you’re an individual who wants to protect your valuable possessions, foam inserts are a great way to keep them safe and secure.

Why Choose Packaging Kite?

Packaging Kite is the right choice for your custom foam insert needs. We have years of experience designing and manufacturing high quality foam inserts. We offer a wide variety of foam types and cutting techniques to meet your specific needs. We have a team of experienced designers and engineers who can help you create the perfect insert for your product. We are committed to providing excellent customer service. We’ll work with you every step of the way to make sure you’re happy with the final product. We offer competitive pricing and fast turnaround times. We understand that you need your inserts quickly, and we’ll do everything we can to get them to you as soon as possible.

Ordering Your Foam Inserts

Ordering your custom design foam inserts from Packaging Kite is easy. Simply contact us with your requirements. Tell us about the item you want to protect, the quantity you need, and any special features you want. We’ll provide you with a free quote and a design proposal. Once you approve the design, we’ll start the manufacturing process. We’ll keep you updated on the progress of your order and let you know when it’s ready to ship. We ship our foam inserts all over the world. We ensure the inserts are packed well to make sure you receive them in perfect condition. Contact Packaging Kite today to get started on your custom foam insert project. Protect your products, impress your customers, and make Packaging Kite your preferred choice.

Our turnaround time is 8-10 working days. You may shop with us for as low as just 100 pieces. Moreover, your design customizations will be taken care of by our expert designers. You can consult with them to have the most amazing designs for your

Inserts Boxes. Our customer service is available 24/7. You can contact us via live chat, send us an email at

sales@packagingkite.com or simply call at (708) 920-1765 for instant assistance.